A Biased View of Insulated Glazing Panels

Table of ContentsSome Known Incorrect Statements About Fire Rated Glass Vision Panels 10 Easy Facts About Large Double Glazed Glass Panels DescribedGlazed Panel Window Things To Know Before You BuyIndicators on Double Pane Tempered Glass Panels You Should KnowThe Facts About Insulated Glazing Panels UncoveredThe Greatest Guide To Insulated Glazing Panels

Periodically, there are issues relating to having excessive unchecked daylight, in some cases referred to as glow. The difficulty is to strive for the greatest noticeable light passage (VT) and the lowest solar warmth gain coefficient (SHGC) while not avoiding the glass from being also reflective when seen from both the outside as well as the inside, while controlling glow.The devices should be totally assembled in a manufacturing facility and also delivered to the site for setup on the structure. The devices are put on the floors, bundled in dog crates, utilizing the tower crane and also decreased right into place using a smaller crane or hoist had by the glazing specialist. The mullion measurements tend to be slightly larger than a stick system due to their open area as contrasted to television form of a common stick curtain wall area.

The Ultimate Guide To Glazed Window Panels

The interlacing upright mullions will normally have 2 interlocking legs. One leg will remain in the aircraft simply behind the glazing pocket as well as the various other at the interior face of the mullions. The interlocking leg in the plane of the glazing pocket will be secured by gaskets as well as is the primary line of defense versus water as well as air seepage - fire rated glass vision panels.

Solutions whose linking legs lock additionally endanger the capability of the system to fit motion. Some unitized designs are delicate to small irregularities in the spacing of surrounding modules; for example, if the module joints are slightly out of tolerance, gaskets may not be properly compressed and wetness protection may suffer.

Fascination About Glazed Glass Panels

These upstanding legs have gaskets that seal versus the walls of the bottom horizontal. Some layouts supply one upstanding leg that supplies one line of protection against air as well as water infiltration. Extra robust systems will certainly provide 2 upstanding legs with gaskets on both legs. A splice plate or silicone flashing that is set up on top of the two adjacent devices as they are set up on the structure is commonly needed.

The pile joint is the straight joint where devices from adjacent floorings satisfy. Positioning the stack joint at the sill of the vision glass (commonly 30" above the floor) will certainly minimize the dimension of the vertical mullions. This positioning makes use of the back span of the mullion over the anchoring factor at the piece to counteract the deflection of the mullion listed below the piece.

Excitement About Glazed Window Panels

Field screening of drape wall surfaces: Require the field testing of curtain wall surfaces for air infiltration as well as water penetration resistance, for quality assurance of curtain wall fabrication and installation. Require multiple examinations with the initial examination on initial installments and also later tests at roughly 35%, 70% as well as at last conclusion to capture problems early and to verify ongoing workmanship quality. large glazing panels.

The information connected with this section of the BEDG double pane tempered glass panels on the WBDG were developed by board and are planned exclusively as a way to illustrate basic layout as well as building concepts only. Ideal use and application of the concepts highlighted in these details will differ based on performance factors to consider and ecological conditions unique per project and also, as a result, do not represent the last opinion or referral of the author of each section or the board members in charge of the development of the WBDG.

Continual metal sill blinking at the base of the drape wall surface safeguards the wall framework listed below from leak with the curtain wall surface. Sill blinking need to have upturned end dams as well as fully sealed edges. Intermediate straight should be wept to the exterior as well as stop water from draining pipes onto the head of the glazing device below.

Getting The Large Double Glazed Glass Panels To Work

Gasket height should correspond to the curtain wall surface layout pressure. Stress adjusted rainscreen gaskets form a main weather seal at the face of the unitized upright pile joint in line with the horizontal rainscreen gasket at the device sill listed below.

Spandrel glass adapters are made use of to lower the deepness of the glazing pocket to accommodate minimized profile of spandrel glass. Spandrel glass adapters need to be fully bedded in sealer and integrated with polishing pocket edge seals to stop water leak from glazing pocket to structure inside. System measurement of mating head as well as sill squeezed out profiles enables for specified flooring to flooring deflection at the stack joint.

Intermediate horizontals quit at the face of the vertical unit jamb members at each end. Systems are hung from the top or face of the surrounding flooring or building framework utilizing mated brackets as well as area used screws with a minimum of clearance for access as well as setting up. All links and brackets located within the systems shielded or key weather seal zones are sealed with appropriate sealant materials during field setup.

Everything about Double Pane Glass Panels

non-heat-treated) or fully tempered glass to remain in position until it can be replaced. fire rated glass vision panels. Whether heat-strengthened or fully tempered, heat-treated glass items are created in a similar style as well as making use of the exact same processing tools. The glass is heated up to roughly 650 C (1200 F), after that force-cooled to produce surface and also edge compression.

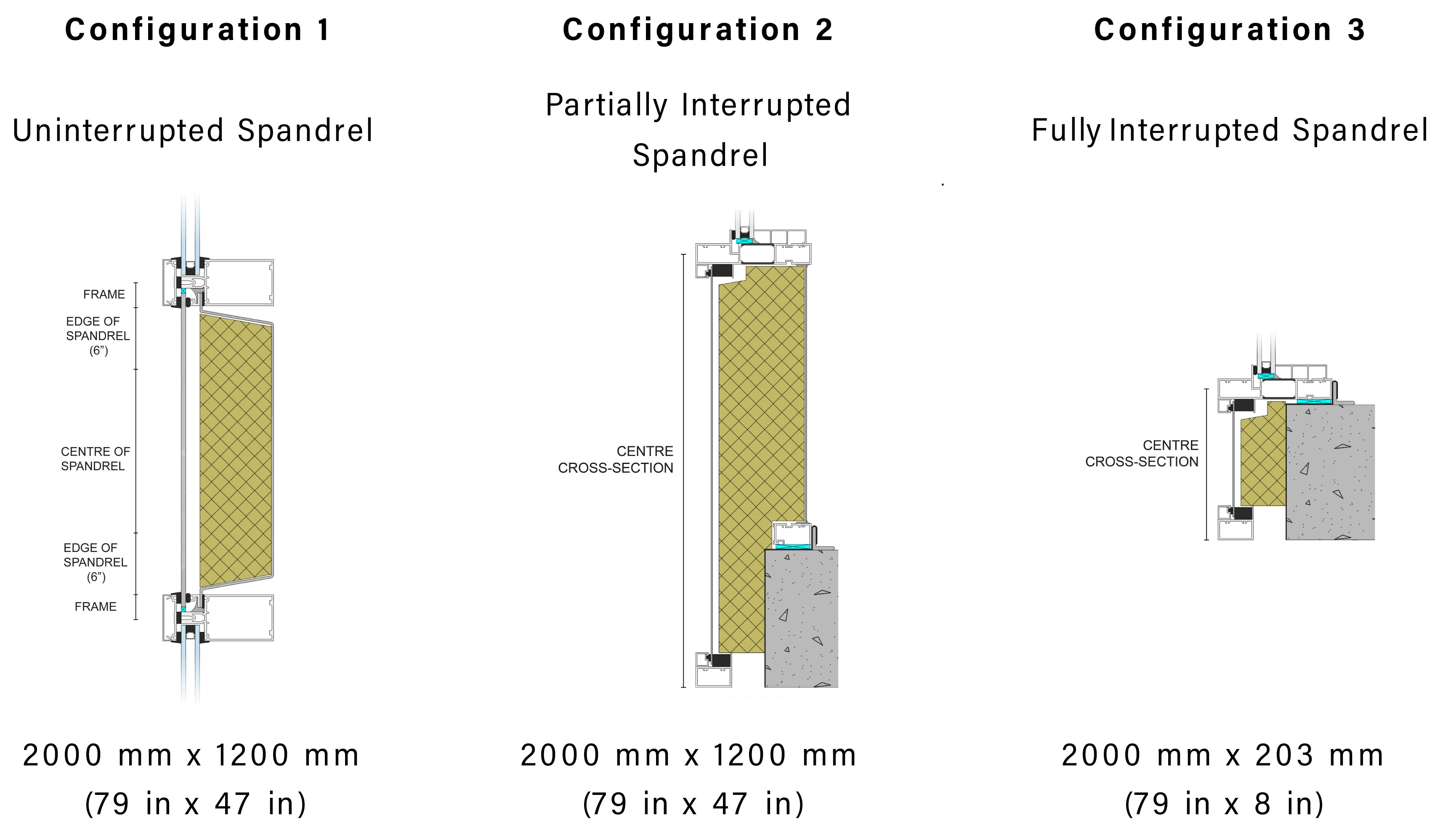

As suggested in Figure 1, insulation is usually made use of together with spandrel glass. When the insulation is to be applied directly to the opacified surface area of the spandrel glass, it is crucial to deal with a glass spandrel producer, in addition to the glue as well as insulation vendors, to guarantee these items work with the opacifying material.